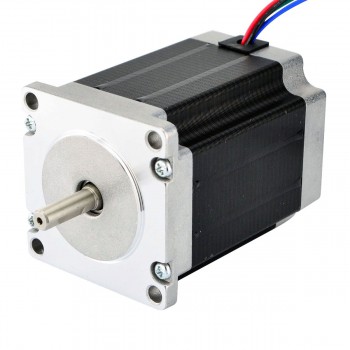

1. Basic structure of hybrid stepper motors

The hybrid stepper motor consists of two parts: the stator and the rotor. The stator usually has 8 poles or 4 poles, with a certain number of small teeth evenly distributed on the pole surface, and the coil on the pole can be energized in two directions. The rotor consists of two tooth plates with a certain number of small teeth evenly distributed on the circumference. The two tooth plates are staggered by half a tooth pitch, and an axially magnetized annular permanent magnet is sandwiched in the middle.

2. Working principle of hybrid stepper motors

The working principle of hybrid stepper motors is to combine the two principles of permanent magnet and variable reluctance. When current passes through the stator winding, a magnetic field is generated, which causes the magnetic poles on the rotor to be attracted or repelled, thereby causing the rotor to move. The rotor of a hybrid stepper motor consists of multiple magnetic poles, usually of two types: single stack and double stack. There is only one permanent magnet pole and multiple variable reluctance poles on the single stack rotor, while there are two permanent magnet poles and multiple variable reluctance poles on the double stack rotor.

3. Selection principles of hybrid stepper motors

1. Load torque: First, you need to determine the torque required for the stepper motor to drag the load. You can measure the load torque by adding a lever to the load shaft and pulling the lever with a spring scale, or directly calculate it theoretically based on the load characteristics. The maximum torque of a stepper motor usually does not exceed 45Nm. The larger the torque, the higher the cost. If the selected motor torque is large or exceeds this range, you can consider adding a reduction device.

2. Maximum operating speed: The speed of the stepper motor has an important influence on its performance. As the motor speed increases, the torque will decrease, and the speed of the decrease is related to factors such as the drive voltage, phase current, and phase inductance. Generally, the speed of the stepper motor should be controlled within 1500 rpm or 1000 rpm.

3. Step angle: The step angle is an important parameter to measure the accuracy of the stepper motor. The step angle of the hybrid stepper motor is usually small, such as 1.8 degrees or 0.9 degrees, which enables it to achieve high-precision position control.

4. Static torque: Static torque is one of the key parameters to consider when selecting a hybrid stepper motor. Static torque should be selected according to the load characteristics, and should generally be 2-3 times higher than the friction load.

5. Current selection: The current selection of the motor should be determined based on its torque-frequency characteristic trend graph. The working characteristics under different currents are different, so it is necessary to refer to the motor's current-frequency characteristic curve to select the appropriate current.

4. Common application areas of hybrid stepper motors

1. Industrial automation: Hybrid stepper motors are widely used in the field of industrial automation, such as CNC machine tools, packaging equipment, printing machines, textile machines, laser equipment, etc. They are mainly used for precise positioning, feeding, positioning control and stepper drive, etc. .

2. 3D printing: In 3D printing equipment, hybrid stepper motors are often used as drivers for print heads to control the position and speed of the print heads to achieve precise three-dimensional printing.

3. Medical equipment: Hybrid stepper motors are also widely used in medical equipment, such as medical robots, CT scanners, syringe pumps, blood separation equipment, etc. They provide precise motion control and position positioning to meet the requirements of medical equipment for accuracy and reliability.

4. Automotive parts: Hybrid stepper motors can be used in automotive parts, such as automotive electronic injectors, on-board cameras, automatic sunroofs, door locks, etc. Precise position adjustment and motion control are achieved through stepper control.

5. Household appliances: In household appliances, hybrid stepper motors are used to drive actuators in electrical appliances, such as fans, valves, and conveyor belts.

6. Robotics: Hybrid stepper motors are also used in various types of robots, including industrial robots, service robots, medical robots, etc. They provide precise position control and motion control to achieve various tasks and actions of robots.

7. Other applications: Hybrid stepper motors are also used in ATM machines, inkjet printers, engraving machines, photo machines, spraying equipment, computer peripherals and mass storage devices, precision instruments, office automation and other fields. They are particularly suitable for applications requiring smooth operation, low noise, fast response, long service life and high output torque.

Source:https://blog.udn.com/stepperrelation/182668758