| En poursuivant votre navigation sur ce site, vous acceptez l'utilisation de cookies pour vous proposer des services et offres adaptés à vos centres d'intérêt. En savoir plus et gérer ces paramètres. |  |

Blog de tianqiong2019

aide blog-

Working principle and design features of stepper motor brake publié le 14/08/2024 à 10:51

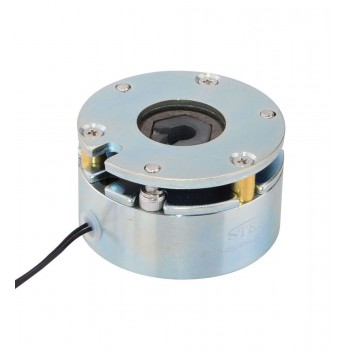

1.Definition of stepper motor brake

A stepper motor brake is a device used to control the stop or deceleration of a stepper motor. It uses electromagnetic force or mechanical force to brake the stepper motor, ensuring that the motor can stop or decelerate quickly and accurately when needed. The main function of the stepper motor brake is to suspend operation under specific circumstances, provide high-precision motion position control, and ensure stable operation of the project. This brake has the characteristics of simple control and wide application. It is suitable for automation equipment, mechanical processing, printing equipment and other fields, and has become an indispensable part of many industries. 2.Working principle of stepper motor brake

Stepper motor brakes usually include two types: spring type and permanent magnet type. Spring brakes are mainly composed of a stator and a rotor. The stator is equipped with a wound coil, and the rotor is made of a specific friction-resistant material. The friction torque between the rotor and the stator is pressurized by a circumferentially distributed spring, so that the armature and the plate clamp the rotor to generate a friction torque. When the coil of the brake is energized, the coil generates a magnetic field, and the armature is attracted to the yoke by the magnetic force and disengaged from the brake disc. At this time, the brake disc is rotated normally by the motor shaft; when the coil is de-energized, the magnetic field disappears, and the armature is pushed to the brake disc by the force of the spring, generating friction torque and braking. Permanent magnet brakes have a faster response speed and can be locked within 50ms. They have the advantages of low noise and less heat. They can be powered on or off, but power-off brakes are more commonly used. This type of brake uses the magnetic field of the permanent magnet to achieve rapid braking, which is suitable for application scenarios that require rapid stopping or maintaining a specific position.3.Design features of stepper motor brakes

1.Modular design: Stepper brakes adopt modular design, which makes the application range wide and can meet various application requirements through the combination of different modules. This design is highly flexible and can adapt to different working environments and requirements.

2.High voltage resistance and good insulation: The REB04 series stepper brake has excellent high voltage resistance and insulation performance, and the insulation level reaches Class F (155°C). This feature enables the stepper brake to operate stably for a long time in harsh or special working environments.

3.Low noise: The stepper brake has low working noise, which is particularly important for occasions that require silent operation. It can reduce interference with the surrounding environment and improve the operation quality of the overall system.

4.Wide range of applications: Due to its design characteristics and excellent performance, the stepper brake is widely used in various working environments, including special environments that require higher insulation levels, showing its wide application potential in different fields.

4.Application fields of stepper motor brakes

1.CNC machine tools: In the field of industrial automation, stepper motors, as an important driving device, are widely used in CNC machine tools to achieve high-precision positioning and motion control. The fast response ability and accurate execution of stepper motors play a key role in the production line and improve production efficiency.

2.Printing machine: Stepper motors are also widely used in printing equipment, providing stable rotation speed and rotation angle, achieving efficient energy conversion, and facilitating the operation of printing equipment.

3.Robotics: In robotics, stepper motors are an indispensable key component. Various joints and actuators of robots need to use stepper motors to achieve accurate motion control and positioning. The high precision and programmability of stepper motors enable robots to complete various complex tasks.

4.Aerospace: Stepper motor brakes have the advantages of fast speed and high precision. They are widely used in the aerospace field to improve the safety and stability of aircraft. With the advancement of technology, the development of stepper motor brakes will pay more attention to improving braking efficiency and reliability. This includes improving the design and materials of brakes to reduce braking time and improve braking efficiency. In addition, in order to meet the needs of different applications, stepper motor brakes will also develop in the direction of smaller and lighter weight to adapt to the space and weight limitations of various equipment and systems.

In terms of noise and heat generation, the improvement of stepper motor brakes will be committed to reducing noise and heat generation. For example, the use of permanent magnet brakes can provide faster braking response, lower noise and less heat, which helps improve the overall performance and service life of the stepper motor.

(0) commentaires

ARCHIVES

"Jean-Michel Berille, le responsable des télé-conseillers." |

- Méthode Savoir Maigrir |

|

ACCUEIL

COACHING

|

PREMIUM

FORUM PREMIUM

|

COMMUNAUTÉ

FORUM

|

RUBRIQUES

DOSSIERS

|

GUIDES

PLUS

|

|

||||||

|

|

|

|||||

|

|

||||||

|

|

||||||

|

|

|

|||||

|

|

||||||

|

|

Tags : ventre plat | maigrir des fesses | abdominaux | régime américain | régime mayo | régime protéiné | maigrir du ventre | |

|

|

|

Découvrez aussi : exercices abdominaux | recette wok | |

|

|

|

|

|

ANXA Partenaires : Recette de cuisine | Recette cuisine | |

|