| En poursuivant votre navigation sur ce site, vous acceptez l'utilisation de cookies pour vous proposer des services et offres adaptés à vos centres d'intérêt. En savoir plus et gérer ces paramètres. |  |

Blog de tianqiong2019

aide blog-

Methods to improve the stability of hollow shaft stepper motors publié le 26/07/2024 à 10:32

1.Introduction

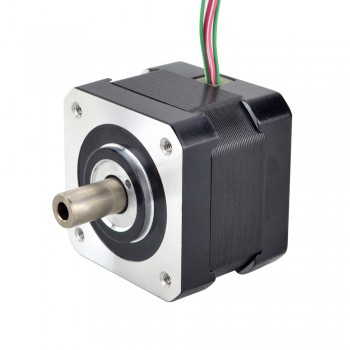

The principle of hollow shaft stepper motors Hollow shaft stepper motors are devices that convert electrical signals into mechanical motion. It consists of a rotor and a stator, and the electromagnetic field in the stator acts on the rotor to make it rotate. Hollow shaft stepper motors use stepper drivers to control the step and speed of the motor by inputting specific pulse signals.2.Features

Features of hollow shaft stepper motors Hollow shaft stepper motors have the following characteristics:1.Hollow shaft design: Compared with traditional motors, the center of the rotor of hollow shaft stepper motors is empty and can pass through the axis, which is suitable for applications where other equipment or transmission parts need to pass through the rotor shaft.

2.High-precision positioning: Since each step and angle of rotation are controllable, hollow shaft stepper motors can achieve high-precision positioning motion to meet the needs of high-demand industrial applications.

3.High efficiency: Due to the use of digital control technology, hollow shaft stepper motors can provide high-efficiency operation with high precision and save energy.

4.Programmability: Hollow shaft stepper motors can be programmed to control their operating modes and parameters, and can be adjusted according to different application requirements, with good flexibility and scalability.3.Methods to improve stability

1.Use micro-stepping drivers: Micro-stepping drivers can improve the resolution of stepper motors, enabling them to make smaller micro-stepping movements between each step, thereby achieving smoother and more precise movements. This helps reduce the vibration and noise of the motor and improve the smoothness of operation. 2.Introduce closed-loop control systems: By introducing closed-loop control systems, such as stepper motor servo systems, the movement of the motor can be adjusted in real time through feedback mechanisms, improving positioning accuracy and dynamic performance. This control method can suppress resonance to a certain extent and improve the stability and accuracy of the motor's operation.

3.Accurately control current: Using advanced current control technology, such as constant current control, can reduce the vibration and noise of the motor and further improve the smoothness of the motor's operation.

4.Reduce load inertia: By optimizing the mechanical system design and reducing the load, it helps to improve the acceleration and deceleration performance of the motor and reduce unstable factors in operation.

5.Implement proper thermal management: Ensure that the motor operates within the temperature range of efficient operation, reduce heat loss, and maintain stable motor performance.

6.Use high-precision magnets and windings: Using high-precision magnets and winding materials can improve the efficiency and performance of the motor and reduce unstable factors in operation.

7. Optimize control algorithms: Using more advanced control algorithms, such as adaptive control, optimal control, etc., can better adapt to different working conditions and improve the performance and stability of stepper motors.

8. Customized design: Customized design for specific application scenarios allows stepper motors to better meet specific needs, thereby improving the stability of operation

(0) commentaires

ARCHIVES

"Jean-Michel Berille, le responsable des télé-conseillers." |

- Méthode Savoir Maigrir |

|

ACCUEIL

COACHING

|

PREMIUM

FORUM PREMIUM

|

COMMUNAUTÉ

FORUM

|

RUBRIQUES

DOSSIERS

|

GUIDES

PLUS

|

|

||||||

|

|

|

|||||

|

|

||||||

|

|

||||||

|

|

|

|||||

|

|

||||||

|

|

Tags : ventre plat | maigrir des fesses | abdominaux | régime américain | régime mayo | régime protéiné | maigrir du ventre | |

|

|

|

Découvrez aussi : exercices abdominaux | recette wok | |

|

|

|

|

|

ANXA Partenaires : Recette de cuisine | Recette cuisine | |

|