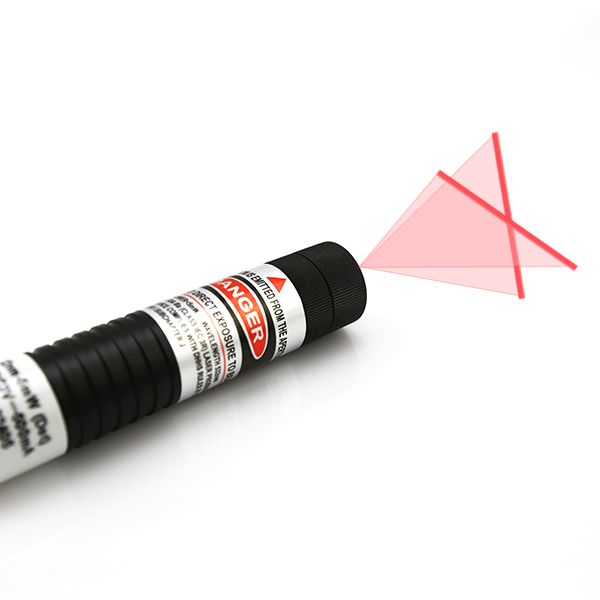

What is a good job for engineers and factory workers to make ultra clear and precise cross line projection in machinery processing work fields? It is not simply rely on any prior cross line drawing or printing work, not limited by long distance, high height and other harsh working environments etc, it would be a much better solution for engineers to apply a highly bright light emitted tool of a 650nm red cross line laser module. It keeps work with intense and powerful red laser light emission from an import laser diode. Furthermore, owing to the mature 650nm red laser diode tech and mass production, the finished product of a red cross laser alignment is always gets quite stable performance, low production cost, and long term lasted red vertical and horizontal lines generation onto multiple working surfaces conveniently.

Basically 650nm wavelength red light projects high sensitivity and high brightness red laser light from an import 650nm red laser diode directly. When red laser diode module is designed with wide range output power of 5mW to 100mW and 150mW to 500mW, equipped with a metal heat sink cooling system inside its sealed anodized aluminum alloy housing tube, it always gets superior nice heat dissipation, and increasing stability red cross line projection in continuous use. Basically this red cross laser alignment supports constant work within 10 hours per day, unaffected by overheating and over current impact as well. Owing to its clearly visible red light emission to the naked eyes, it still develops even in strong light environments, eliminating the need of light shielding and maintaining efficiency.

Based on the adoption of a qualified glass coated lens with 10, 15 and 110 degree fan angles, whatever kind of working surface it is pointing, 650nm red cross line laser module is projecting high linear quality and highly straight red cross line source within 0.5 meter to 6 meters length in distance. Cooperated with its low laser beam divergence of less than 1mrad and adjustable focus optic lens design, this red cross laser alignment enables ultra high fineness of ≤ 0.8mm at 3 meters, and positioning error < 0.1mm, suitable for precision machining needs. Under operation within APC, ACC driving circuit board design, whatever output power it is selected, it keeps work with stable red cross line projection, and long serving lifetime of more than 8,000 hours in continuous use.

Applications in machining scenarios:

Metal Cutting Positioning: Alignment of the cutting machine's optical path; crosshair positioning determines the starting point/cutting kerf, reducing material waste.

Welding Alignment: 650nm red alignment laser makes precise marking of weld seams, and assists in welding torch positioning, improving weld straightness and fit.

Woodworking Machinery Guidance: Uses crosshair reference lines on panel saws/engraving machines to quickly align wood cutting points, improving cutting accuracy.

Mold Processing Alignment: Positioning reference during mold grooving/drilling, ensuring precise hole/groove spacing.

CNC Machine Tool Assistance: Workpiece alignment before CNC machining, shortening clamping and calibration time.