| En poursuivant votre navigation sur ce site, vous acceptez l'utilisation de cookies pour vous proposer des services et offres adaptés à vos centres d'intérêt. En savoir plus et gérer ces paramètres. |  |

Blog de lasermodule

aide blog-

Advanced Use of 650nm Red Cross Line Laser Module in Machining Processing publié le 12/12/2025 à 15:01

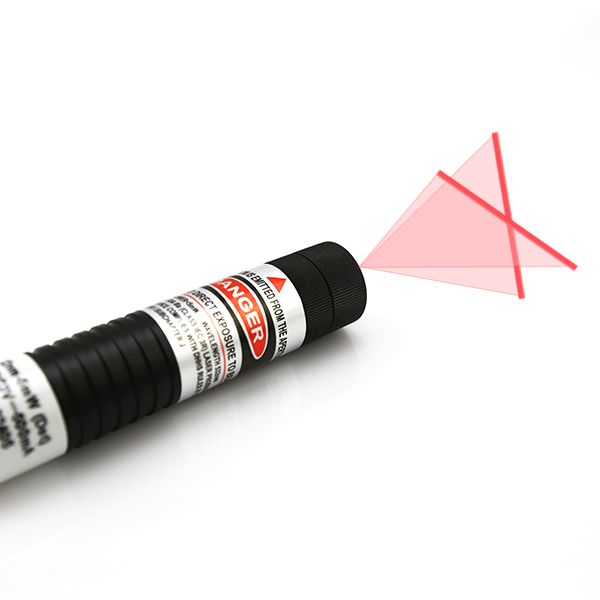

What is a good job to make ultra clear and precise cross line alignment in machining processing works? Not able to rely on any prior cross line drawing or printing work, not limited by long distance or high height, factory workers and engineers would prefer to operate a highly intense beam emitted tool of a 650nm red cross line laser module. Usually it applies a 650nm wavelength red laser diode and a qualified optic lens inside a durable housing tube, which is featured by low production cost, high precision during device positioning work in machining. A correct output power and optic lens fan angle made red cross laser alignment provides a visual reference by projecting orthogonal crosshairs, suitable for various processes such as metal cutting and parts assembly. It can replace traditional ruler marking and is compatible with automated equipment, significantly improving machining accuracy and efficiency.

When cross line projection is processing at different work distances, 650nm red cross line laser module should be working with different dimension cross line source in distance. Besides the adoption of a qualified glass coated lens with 10, 15 and 110 degree fan angles, it is also equipped with an adjustable focus optic lens. Whenever it projects highly straight and fine red cross line within 0.5 meter to 6 meters length, after its immediate red laser light concentration, red cross laser alignment gets increasing brightness and fineness cross line alignment at a longer distance and multiple lighting occasions as well. Whenever it gets high straightness and small perpendicularity error, it can greatly avoid the cumulative errors of manual marking. Owing to its high sensitivity red laser light emission to the human eye, it can still make clear cross line indication in strong sunlight or cutting dust environments.

When 650nm red cross line laser module applies different dimension tube diameter for different output power range, it can be easily installed on the vertical and horizontal surfaces of machine tools, saws, drilling machines and other processing equipment. Within freely installed distance of 3 meters and three dimensional adjusted spaces, it is adapted to the positioning needs of different processing stations. This red cross laser alignment utilizes all metal coating, providing both heat dissipation and ant static properties. Featured by long serving lifetime and high stability laser beam emission, it is suitable for long term continuous machining operations effectively.

General applications in machining processing:

Metal cutting positioning: On metal cutting machines, sheet metal shearing machines, and other equipment, 650nm red cross line laser module can mark the cutting lines and edge alignment references for steel plates and profiles, avoiding the problem of manual markings being covered by coolant during the processing of cold and hot steel plates.

Component Drilling and Grooving Alignment: When machining mechanical parts on CNC drilling and milling machines, the intersection of red cross lines can precisely align the machining starting points for hinge holes, threaded holes, tenons, etc.

Automated Assembly and Equipment Debugging: In industrial robot assembly lines and automated production lines, red alignment laser can assist in positioning mechanical components to be assembled, ensuring accurate alignment of bearings, gears, and other parts.

Precision Instrument Parts Machining: In the machining of instrument parts such as micro gears and precision bushings, red cross lines mark the symmetrical center line and the machining reference origin, enabling micron-level positioning in conjunction with precision machining equipment, meeting the machining requirements of precision mechanical parts in medical devices and electronic equipment.

(0) commentaires

ARCHIVES

"Jean-Michel Berille, le responsable des télé-conseillers." |

- Méthode Savoir Maigrir |

|

ACCUEIL

COACHING

|

PREMIUM

FORUM PREMIUM

|

COMMUNAUTÉ

FORUM

|

RUBRIQUES

DOSSIERS

|

GUIDES

PLUS

|

|

||||||

|

|

|

|||||

|

|

||||||

|

|

||||||

|

|

|

|||||

|

|

||||||

|

|

Tags : ventre plat | maigrir des fesses | abdominaux | régime américain | régime mayo | régime protéiné | maigrir du ventre | |

|

|

|

Découvrez aussi : exercices abdominaux | recette wok | |

|

|

|

|

|

ANXA Partenaires : Recette de cuisine | Recette cuisine | |

|