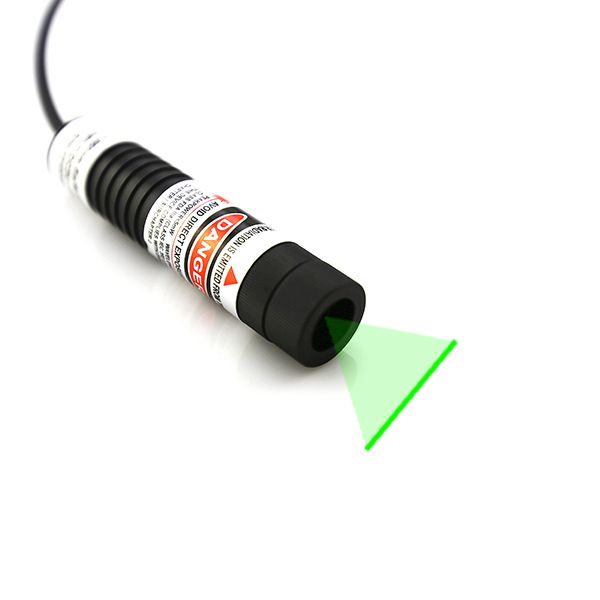

Not able to rely on any prior line drawing or printing work, in order to make clear and precise enough line indication onto various stone raw material surfaces, it would be an efficient job to apply a highly intense beam emitted tool of a 515nm green laser line generator. It is projecting highly penetrated and highly bright forest green laser light source directly from an import 515nm green laser diode. When it is making line indication for stone processing sites, such as outdoor construction or strong workshop lighting, green line laser alignment can still produce a clear and conspicuous straight green reference line, resulting in extremely high positioning accuracy.

Usually a 515nm green laser line generator applies an AC/DC adapter, not spending prior time on battery change, it can make continuous green laser beam emission from an import laser diode within 50mW to 200mW. For the most important of all, besides its basic use of a metal heat sink cooling system, it also gets special use of APC, ACC intelligent feedback driving circuit board, whatever output power it is selected, green line laser alignment enables constant green reference line projection continuously with other stone processing machine or device. It gets no effect by increasing temperature and serious electric current impact as well. Whenever it keeps work with highly fine and straight green line projection, it can also enables good straightness, with positioning errors controllable within ±0.1-0.3mm. This meets the requirements for high-precision stone cutting and splicing, reducing stone waste caused by positioning deviations.

Basically 515nm green laser line generator applies ultra compact size tube design, allowing for flexible installation on various stone processing equipment, such as cutting machines, carving machines, grinding machines, and it is compatible with different thicknesses and materials of stone (marble, granite, artificial stone, etc.), suitable for various indoor and outdoor processing scenarios. When it is made with durable anodized aluminum alloy housing tube, even though it is used under harsh processing environments, this green line laser alignment still processes excellent vibration and interference resistance. Vibrations during the operation of stone processing equipment will not affect the stability of the laser line; some waterproof and dustproof models are suitable for outdoor humid and dusty processing environments, and have a long service life. Highly straight green line projection also makes a good job for shortening positioning time, improving stone processing efficiency, and reducing the error rate of manual positioning.

General applications in stone processing works:

Stone Cutting and Positioning: 515nm green laser line generator is used with stone cutting machines and bridge cutting machines, it projects a clear green linear line to precisely mark the cutting path, such as straight cutting and dimensional trimming of marble and granite slabs, preventing cutting deviation.

Stone Layout and Assembly: Before stone laying and assembly, the linear laser calibrates the gaps between stone joints, ensuring that multiple pieces of stone are aligned and flat. Suitable for the layout of wall and floor stone installations.

Stone Carving Positioning: 515nm green alignment laser assists stone carving machines in positioning the outline and baseline of carved patterns, clarifying the starting position and range of carving, improving the accuracy of carved patterns, and adapting to processes such as relief carving and text carving.

Stone Grinding and Calibration: During stone surface grinding and polishing, the laser linear line is used as a reference to judge the flatness of the stone surface, avoiding unevenness after grinding. Suitable for fine grinding of stone panels and countertops.