First, we will go over the most common mechanical methods to reduce vibration in stepper motors.

1. Install a mechanical clean damper.

An easy method to reduce vibration is to install a clean damper on the rear shaft of the motor. Clean dampers are basically hermetically sealed plastic cases with an inertia body packed with silicon gel. The extra inertia and silicon gel help absorb the vibration and provides a stable damping effect.

2. Use a high resolution type stepper motor.

Some motor manufacturers provide stepper motors with an increased number of rotor teeth (100 instead of 50). The increased number of teeth doubles the full-step resolution and helps reduce the amplitude of vibration since the motor is now moving a shorter distance with each step. This means that the standard 1.8° 2-phase stepper motor becomes a 0.9° motor, and a standard 0.72° 5-phase stepper motor becomes a 0.36° motor.

3. Use a 5-phase stepper motor.

Similar to a high resolution type stepper motor, a 5-phase 0.72° stepper motor can also achieve a finer full-step resolution and reduce vibration compared to a 2-phase 1.8° stepper motor. Compared to a 2-phase motor, a 5-phase motor has the same rotor but 10 stator poles instead of This increases the full step resolution from 200 to 500 steps per revolution.

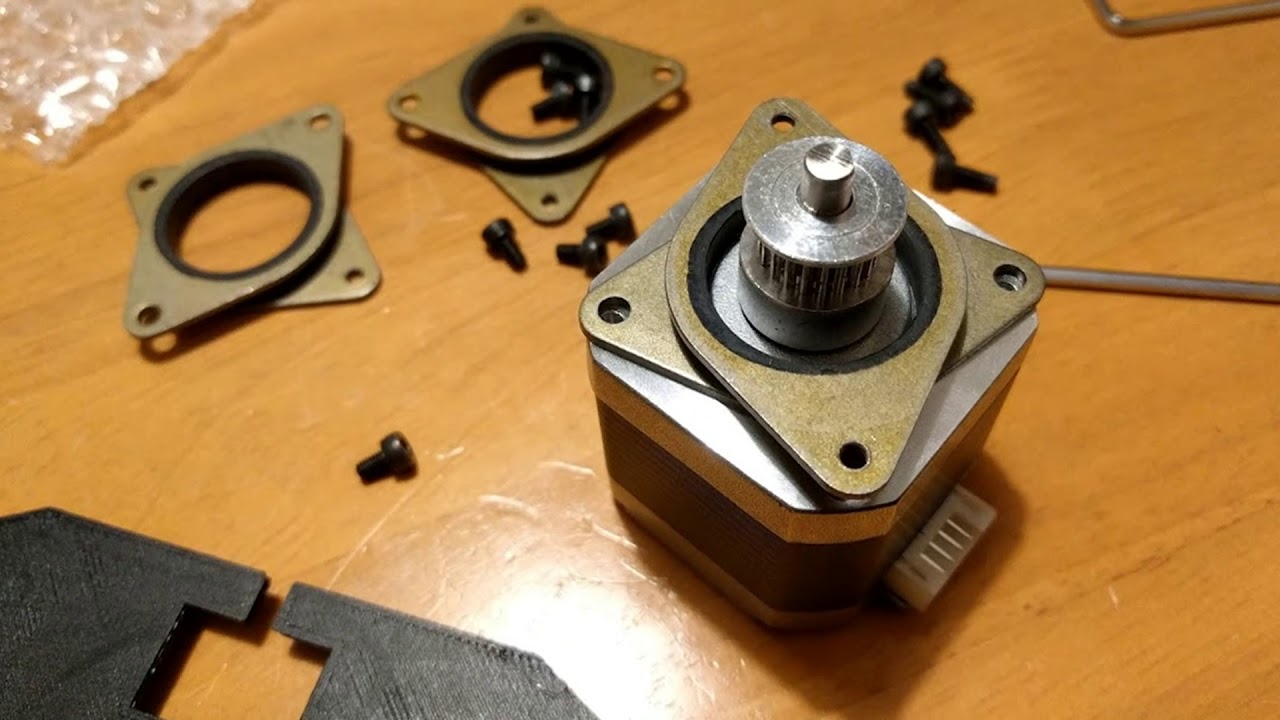

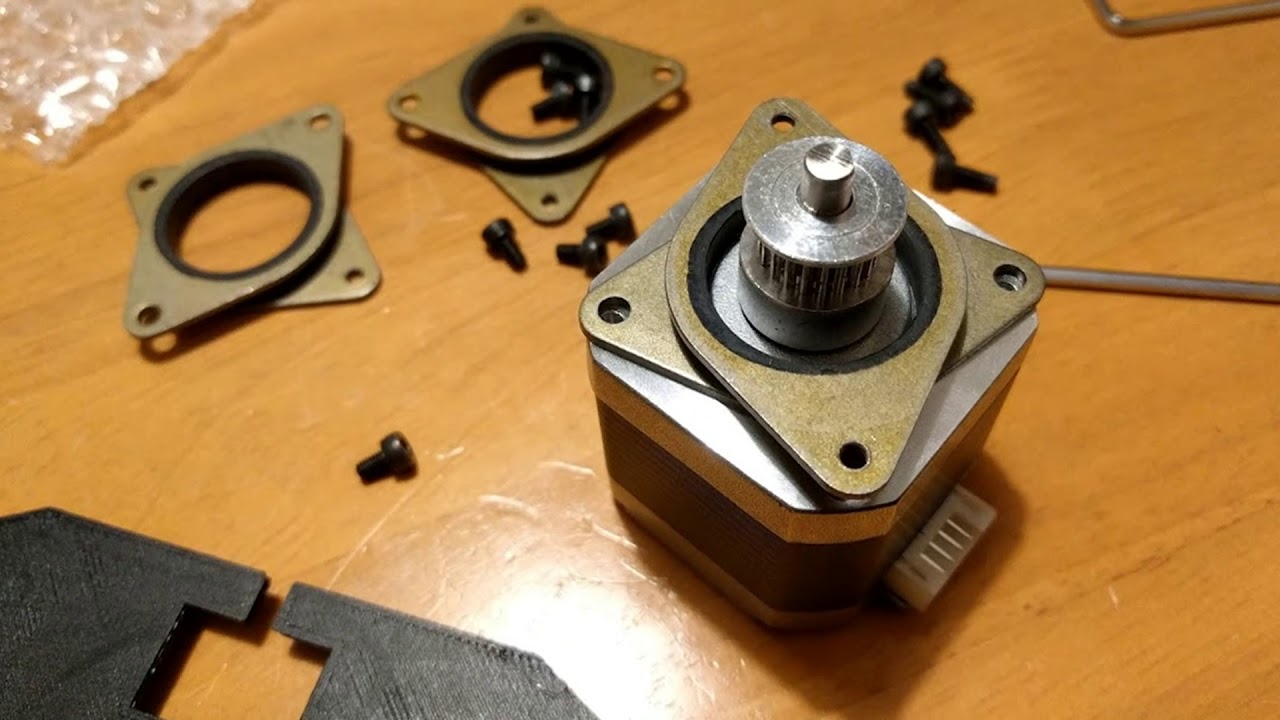

4. Use geared stepper motors.

A gearhead is generally used to increase torque while reducing speed of a motor, but the increased rigidity can help suppress the transmission of vibration from motor to load, gear friction can help reduce overshooting and undershooting, and its consistent torque output can provide more stable operation.

5. Perform a thorough sizing of the motor.

Sizing a motor involves finding that "sweet spot" where the motor can operate comfortably. It is a mistake to try to size a motor for its maximum specifications. For example, a nema 17 stepper motor's speed-torque curve depicts where the motor will stall, so sizing a motor exactly at these specifications is definitely not recommended. It's also important not to oversize the motor too much since the excessive torque may increase the amount of vibration. If you do oversize a stepper motor, you can reduce the excessive torque by reducing the motor current (hint: current is proportional to torque).